China Sheet Metal Brackets Manufacturers, Suppliers, Factory

Huaner is a professional China sheet metal brackets manufacturers and China sheet metal brackets suppliers, supporting the production of high-quality bracket products, bracket is produced through the combination of sheet metal stamping, bending and welding technology, and can be customized according to specific requirements to make customers satisfied with the bracket series products, the following are the steps required for the production of sheet metal brackets, but also in the communication must confirm good details:

1. Prepare materials: Select appropriate materials, such as metal, plastic, wood, etc., according to the type of support required.

2. Design the support structure: Before making the support, design the structure and size of the support.

3. Cutting material: According to the sheet metal brackets design drawings, use cutting equipment (such as sawing machine, laser cutting machine, etc.) to cut the material into the desired shape and size.

4. Welding and assembly: the cut material is welded and assembled. High welding quality is required to ensure the rigidity and stability of the support.

5. Surface treatment: In order to improve the corrosion resistance and aesthetics of the sheet metal brackets , it is necessary to carry out surface treatment of the bracket. Common surface treatment methods include spray painting, electroplating, hot dip galvanizing and so on.

6. Qualified inspection: After the stent is made, the quality inspection is carried out. The inspection items include the size, stability and bearing capacity of the support. Ensure that the sheet metal brackets complies with design requirements and relevant regulations.

7. Installation and debugging: Install the qualified support to the specified position, and debug. During the debugging process, ensure that the support is stable, no shaking, and the bearing capacity meets the requirements.

8. Delivery: Acceptance shall be carried out after installation and debugging of the support. After acceptance, the support shall be delivered to the user. During use, the sheet metal brackets should be checked and maintained regularly to ensure its safety and reliability.

- View as

Heavy Duty Mounting Shelf Brackets

Heavy duty mounting shelf brackets is heavy-duty partition bracket, which can hold up to 40 pounds, ensures that the wall bracket is mounted directly to the wall. Depending on the weight of the industrial shelf, we can easily install a bracket every 14-30 inches. Our heavy duty mounting shelf brackets high-quality galvanized steel pipe is made to ensure that each square pipe is straight, the surface treatment is powder-coated to prevent rust, in order to extend the service life, with two holes to fix the plate, will be more stable than the single-hole bracket.

Read MoreSend InquiryAngle Brackets For Wood House Constructions

Standard Thick Galvanized DecorativeWood Angle Stainless Steel Corner Bracketfor securing wooden frames tables chairs bed furniture and other DIY structural.TheAngle brackets for wood house constructionsis made of high-quality stainless steel, which is rust-proof, sturdy and durable, and has smooth edges without burrs, so you don't have to worry about scratching your hands during use of the furniture.

Read MoreSend InquiryFurniture table chair legs brackets

The Furniture table chair legs brackets are made of stainless steel ,Iron, heavy gauge steel , can be used in dining tables, conference tables, desks, and coffee tables to emphasize the free modern style. The design is simple and atmospheric, simple and beautiful, the structure is simple and firm, do not use a screw. Surface treatment using high-temperature baking paint can play a durable anti-scratch paint role.

Read MoreSend InquiryMounting Stainless Steel Brackets With Screws

The latest selling Mounting stainless steel brackets with screws are made of stainless steel with a powder spraying process. They can be used in the bathroom, kitchen and living room to emphasize a free modern style. Xiamen Huaner Technology Co., Ltd., a sheet metal process manufacturer in China, has gradually enriched on the basis of sheet metal production process, and now it can produce unique high-quality mounting stainless steel brackets with screws, which are involved in architectural furniture and even art.

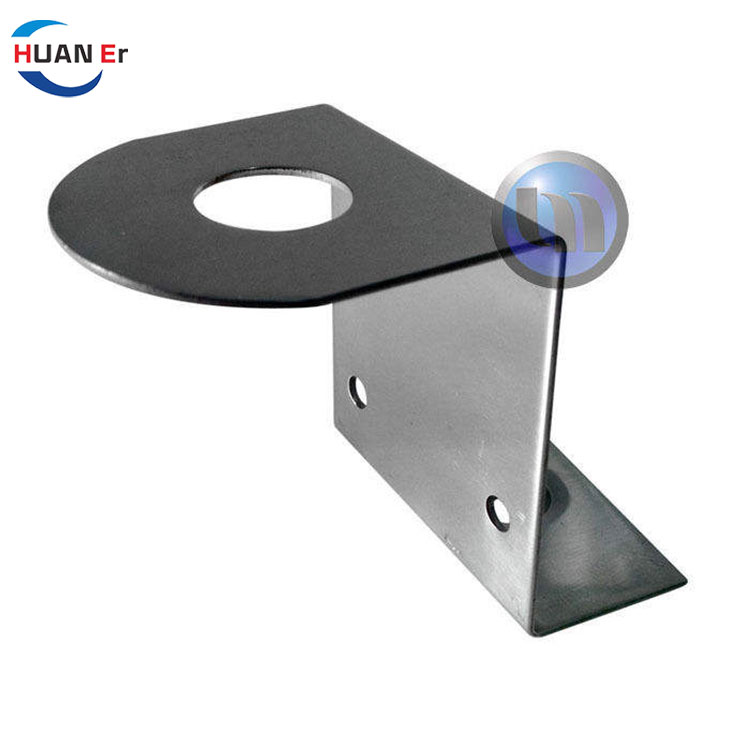

Read MoreSend InquiryZ Type Wall Mounting Brackets

High-quality zinc/nickel plated steel Z Type Wall Mounting Brackets with powder-coated surface,with Mounting Screws,is suitable for Furniture Shelf Iron

Read MoreSend InquiryFixing Brackets

Are you unsure if the mounting fixing brackets you plan to use can sustain your shelving? Even the heaviest shelving loads can be supported by the great compressive strength of our metal fixing brackets. The sort of wall you have is the most crucial consideration when fixing your brackets. Only the wall it is fastened to will have the strength to support the bracket.Below are a few of the designs of our metal mounting brackets.

Read MoreSend InquiryAngle Brackets

Corner brackets, corner braces, and corner fasteners are other names for angle brackets.Light angle brackets are frequently used to reinforce furniture assembly in a wide range of do-it-yourself projects. Angle brackets come in a variety of series, including gusseted, adjustable, and angle brackets with locating holes. All of our angle brackets come in a variety of sizes, with the majority having multiple length options.

Read MoreSend InquiryFunctional Home Decorative Metal Brackets Stamping Parts

Functional home decorative metal brackets stamping parts can produce various types of brackets. These Modern Style Shelf Brackets can be installed anywhere storage is needed. There are different colors surface treatment will go with any décor, and can be used in any environment including retail display, kitchen, bath, office, laundry room or garage. The design of the bracket provides support on the top edge and underneath.

Read MoreSend InquiryTriangle Brackets

Huaner’s decorative triangle brackets are made from high quality steel with powder coating surface treatment. A strong and durable triangle bracket can be used for shelf projects around the home,garage,shed or office.

Read MoreSend Inquiry