China Sound bar brackets Manufacturers, Suppliers, Factory

abide by the contract, conforms towards the market requirement, joins during the market competition by its good quality likewise as provides additional comprehensive and great services for customers to let them turn out to be big winner. The pursue of your enterprise, is the clients' fulfillment for Sound bar brackets,L shelf brackets heavy duty diy open shelving,Cast iron brackets,Pipe clamp brackets,Office divider brackets, Living by good quality, enhancement by credit score is our everlasting pursuit, We firmly think that immediately after your stop by we are going to become long-term companions.

Sound bar brackets, We have been always creating new technology to streamline the production, and offer goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We'll offer you our best service to satisfy all your needs! Be sure to contact us right away!

Hot Products

Stainless Steel Folding Brackets

Stainless Steel Folding Brackets, created by Xiamen Huaner Technology Co., Ltd. are high-quality hardware parts made from premium stainless steel materials for superior corrosion resistance and durability. These brackets are widely used in a variety of applications where temporary support and space optimization is required. Typical applications include folding dining tables in kitchens, folding workbenches in garages, adjustable shelves on balconies, and a variety of temporary worktops.Multifunctional Stainless Steel Stamping Parts Brackets

For more than 16 years, our company has focused on producing various types of multifunctional stainless steel stamping parts brackets. All of our business partners have acknowledged and appreciated the high quality and worldwide popularity of our products. At all times, our business is committed to provide superb client service. We assure that when customers purchase our Small Metal Parts, Stamping Stainless Steel Parts, or Custom Copper Rivet, we will offer them a full spectrum of satisfied services since we truly believe in the customer-first and honesty-based service philosophy.T Shape Brackets

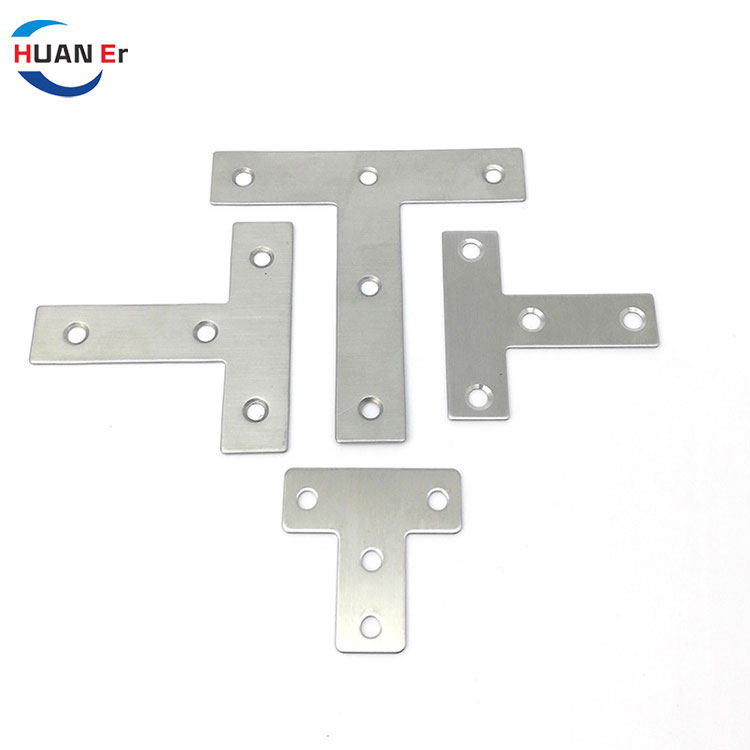

T shape brackets are used to link and secure furniture and household item corners, which can firmly strengthen doors and other items of furniture. Additional corrosion resistance and durability can be provided by steel T shape brackets with a zinc-plated finish. It is available in silver, which goes well with the decor of most homes.Steel Wall Hook Designs

Xiamen Huaner Technology Co.,Ltd. is a company specializing in Steel Wall Hook Designs, which is dedicated to providing high-quality, innovatively designed and functional products. Their Steel Wall Hooks are durable, stylish and easy to install, meeting the needs of a wide range of items in both domestic and commercial environments. These hooks not only excel in weight bearing and durability, but also enhance the aesthetics of a space through sophisticated design, making them an ideal choice for consumers.Metal Phone Holder Computer Brackets Stand

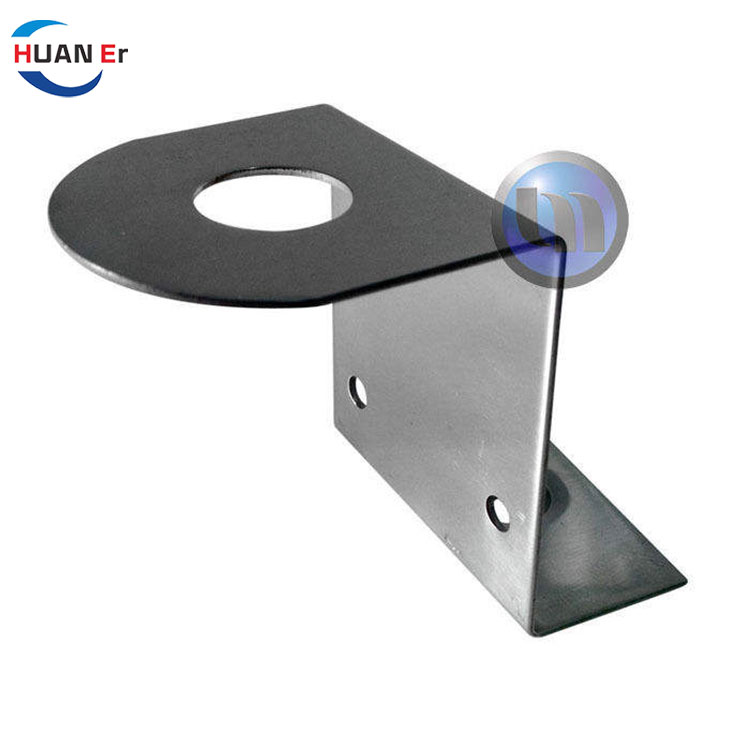

Metal phone holder computer brackets stand is made by a series of processes such as stamping, welding, bending and so on. Xiamen Huaner Technology Co., LTD., in the process of metal phone holder computer brackets stand manufacturing, the raw materials are laser cut and then punched, trimmed, painted and other processes make the products beautiful and convenient.Zinc Alloy Die Casting Auto Parts

Huaner has professional experience in producing zinc alloy die casting auto parts for more than 16 years.Zinc alloy die casting is a popular processing to manufacture high precision, light weight and cost effective auto components.The process involves a mold with a cavity in the shape of the desired part geometry. A pressurizing mechanism pumps molten metal into this cavity and maintain it in high pressure until it cools down.