Products

Huaner has a professional development staff and designers, perfect organizational structure, to provide customers with high quality products and considerate service.We have a complete channel from product design, development, production to sales.

- View as

Zinc Die Casting Components

Zinc die casting is a process that involves melting zinc alloys and inject zinc alloy into a ready die casting mold. Zinc alloys are widely used in manufacturing spare parts because of their ductility, impact strength, and low melting point.The produced zinc die casting components have many advantages.

Read MoreSend InquiryZinc Alloy Die Casting Spare Parts

Huaner is professional in producing zinc alloy die casting spare parts with high tolerence. Our zinc alloy die casting spare parts are commonly used in industrial applications due to their favorable casting characteristics which include: High density and high ductility.

Read MoreSend InquiryZinc Die Casting Parts

Huaner produces high-quality zinc die casting parts in sizes ranging from tiny and light to large and heavy. We offer a variety of surface treatments for zinc die casting parts, including powder coating, sandblasting, chrome plating, and bright polishing. The automotive, food and beverage, machinery, plumbing, irrigation, mining, petrochemical, electrical, energy, aerospace, submarine, and other industries can all benefit from our zinc die casting services.

Read MoreSend InquiryCNC Turning Machining Parts

Classy CNC turning machining parts is a kind of CNC machining, Xiamen Huaner Technology Co., Ltd. can use customized CNC turning processing to make round, cylindrical, conical CNC turning parts. Although it is not as versatile as CNC milling, it is one of the most popular CNC machining services and rapid prototyping services.

Read MoreSend InquiryCNC Milling Machining

Xiamen Huaner Technology Co., Ltd. is a series of high-quality CNC accessories through CNC milling machining factory, and has a wide range of applications.One of the most popular types of CNC machining is CNC milling machining, which can be used to create custom working prototypes or various CNC machined parts.

Read MoreSend InquiryCNC Lathe Parts

Xiamen Huaner Technology Co., Ltd. is CNC turning parts , CNC lathe parts, CNC turning parts and CNC milling machine parts manufacturer. We have advanced production equipment and technology, as well as experienced technical team, to provide customers with high quality, efficient and accurate CNC lathe parts processing services in China.

Read MoreSend InquiryCNC Machining Fastener for Mechanical Industry

Huaner has professional experience in producing CNC Machining Fastener For Mechanical Industry for more than 16 years. Fasteners are a kind of mechanical parts that joins or affixes two or more objects together mechanically, which can be widely used in different industries, including energy, electronics, electrical, mechanical, chemical, metallurgy, mold, hydraulic and other industries. In various machinery or equipment, you can see a wide range of cnc machined fasteners.

Read MoreSend Inquiry3 Axis 4 Axis 5 Axis CNC Turning and Milling Machining Parts

Xiamen Huaner Technology Co.,Ltd is CNC machining service manufacturer and supplier in China. for both prototypes and machined parts of end-use. We provide wide ranges of CNC machine seivices including 3 axis 4 axis 5 axis cnc turning and milling machining parts as well as drilling,tapping,electrical discharge machining and wire EDM.

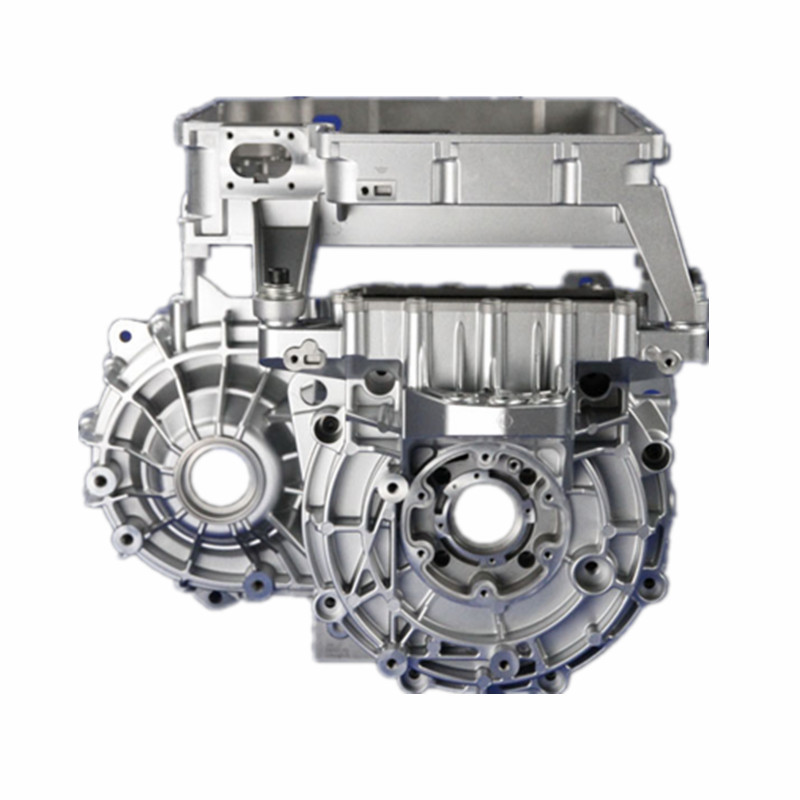

Read MoreSend InquiryHigh Pressure Die Casting Parts

High Pressure Die Casting is an extremely efficient manufacturing method for producing various high pressure die casting parts forms. The process forces molten metal at high speed, and high pressure into a closed steel die cavity. The die has a stationary and moving half, both of which are mounted to the die casting machine’s platens. The die casting machine has an injection end that uses hydraulics and pressurized gas to move a piston forward, injecting the molten metal into the closed steel die. The die casting machine also has a clamping end that utilizes hydraulics and mechanical toggles to absorb the injection pressure and hold the die shut while the part solidifies. The process is capable of turning molten metal into a solid near-net-shape part in seconds.

Read MoreSend Inquiry