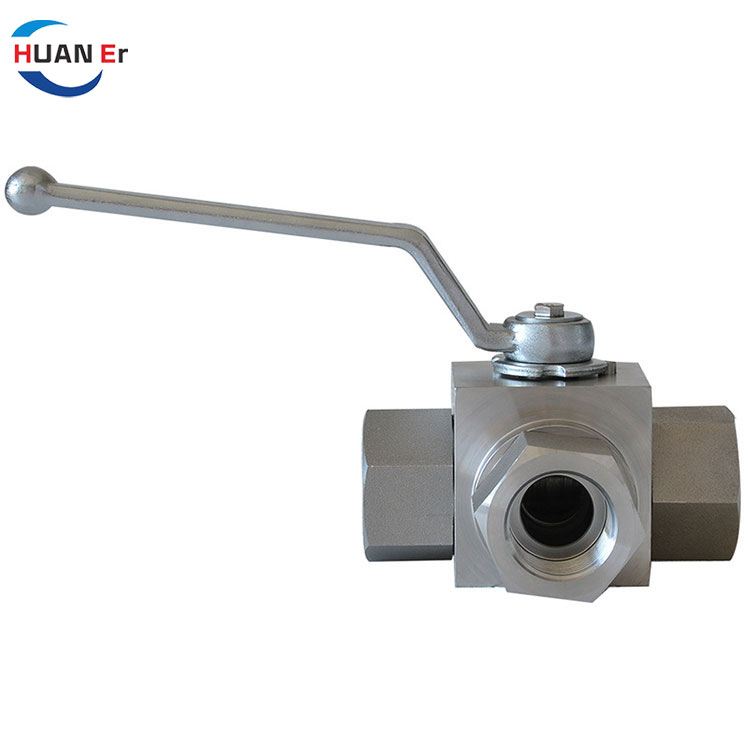

3 Way Ball Valve

Xiamen Huaner Technology Co., Ltd. is a professional manufacturer of 3 Way Ball Valve, which is dedicated to providing high-quality and high-performance fluid control solutions. Our 3 Way Ball Valves are widely used in petroleum, chemical, water treatment and other fields because of their durability, easy operation and excellent sealing performance. With advanced production equipment and strict quality control, we not only provide cost-effective products, but also customized solutions to meet diversified application needs.

Send Inquiry

3 way ball valve

Xiamen Huaner Technology Co., Ltd. are3-way ball valve manufacturers and supplier. Itis a versatile and widely used valve in various industries,including oil and gas, chemical, pharmaceutical, and food processing. This type of valve offers numerous advantages due to its simple design, high flow efficiency, and low maintenance requirements.

Huaner is a die casting manufacturer with excellent technology in the field of ball valve production. The3 wayball valve produced by the company not only has exquisite technology, but also has reached the industry-leading level in terms of efficient and high-precision control. In the medical field, precise control is essential. Whether it is the disinfection of medical devices or the accuracy of the drug ratio, the valve is required to have a high degree of stability and reliability. Huaner3 wayball valve is also widely used in home furnaces, water treatment and other fields. Whether it is the daily water treatment of families or large-scale water purification projects, Huaner's ball valve has won the praise of users for its efficient and stable performance.

Advantages of 3-way Ball Valves

1. Ease of Operation:3 way ball valves are designed with a simple ON/OFF mechanism, making them easy to operate and control. The ball inside the valve can be rotated90 degrees to switch between open and closed positions, allowing for precise flow control.

2. High Flow Efficiency: The 3 way ball valve ensures minimal pressure loss during operation, making it an ideal choice for applications requiring efficient flow control. The full-ported design of the valve allows for unrestricted flow, reducing friction losses and ensuring optimal performance.

3.Low Maintenance: 3 way ball valves require minimal maintenance, making them a cost-effective solution for industries where downtime is a concern. The valve's simple design minimizes the likelihood of mechanical failures, and routine inspection and cleaning procedures can extend its service life.

4. Corrosion Resistance: Many3-way ball valves are made from corrosion-resistant materials, such as stainless steel or plastic, making them suitable for use in harsh environments. This feature ensures the valve's durability and longevity in industries where chemicals or other corrosive substances are present.

5. Versatility: 3 way ball valves can be configured to handle various media, including gases, liquids, and slurries. This versatility makes them a popular choice for applications requiring multi-phase flow control.

Product nature

|

Brand |

Huaner |

|

Produce name |

3 way ball valves |

|

Applicable medium |

Double mounted spring return |

|

Action object |

Water |

|

Pressure environment |

2500 PSIG @ 100°F /172 BAR @ 37°C |

|

Driving mode |

Manual operation |

|

Flow direction |

Internal thread |

|

Accessories available |

0.187 in /4.7 mm |

|

Temperature environment |

Normal temperature |

|

Structural form |

Fixed ball valve |

|

Valve action |

Temperature control |

|

Mode of action |

Double acting |

|

Type (channel location) |

Three-way type |

|

MOQ |

100PCS |

|

Applicable industry |

Industry, fire protection |

|

Sample time |

7-10days |

Maintenance of 3-way Ball Valves

1. Regular Inspection: It is essential to inspect 3 way ball valves regularly for wear and tear, especially in high-pressure or abrasive media applications. Inspect the valve body, bonnet, and seal for any signs of damage or wear.

2. Cleaning: Depending on the media being handled, clean the valve interior and exterior to remove any deposits or buildup that could affect valve performance. Use appropriate cleaning agents to ensure that the valve material is not damaged.

3. Lubrication: Lubricate the3 way ball valves moving parts, such as the ball and seat, to ensure smooth operation and prevent wear. Replace lubricant periodically to maintain optimal performance.

4. Adjustment: Periodically check and adjust the3 way ball valves operating mechanism to ensure proper functioning. Inspect the stem and packing for any signs of wear or leakage.

5. Component Replacement: Replace worn or damaged components, such as seals, O-rings, and stems, to prevent leaks and ensure the valve's proper functioning.